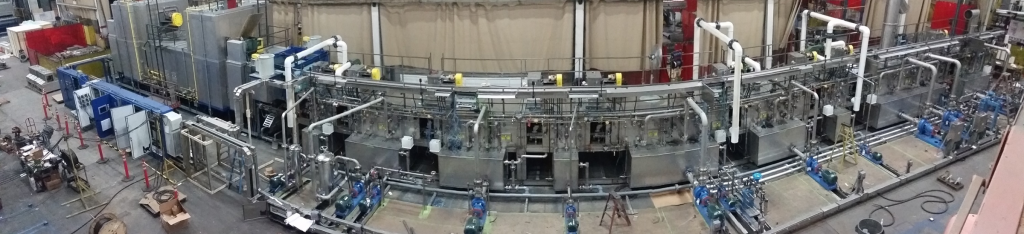

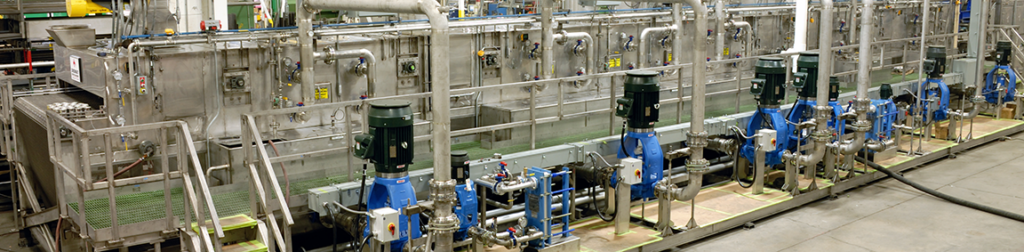

Two-Piece Can Washcoaters

Cincinnati Industrial Machinery’s washcoaters wash and coat the exterior of a two-piece steel food can at speeds of 1,000 to 6,000 cans per minute. Our exclusive triple flow coat curtain design coats the can exteriors completely and protects the cans from corrosion.

We have been leading the industry with our washcoaters industrial equipment, many of which are still in use 40 years or more after installation with extremely high up-time performance. We pride ourselves on the quality of our machines and our customers around the world benefit from this high up-time, low maintenance, and more efficiency in their can washers and ovens. Our state-of-the-art washcoaters are built for maximum efficiency, up-time, and ease of maintenance. Our team of engineers and project managers works with your needs to accommodate various can heights, line configurations, and curing times. We stand behind the quality of our washcoaters and our commitment to total customer satisfaction.

Washcoater Features:

- All stainless-steel construction

- Magnetic transfers from the washer to washcoater and from washcoater to cure oven

- Powered sponge roll assemblies are used to remove the teardrops from the can cut edge

- Three-trough flow coat system

- Three washcoater blow-offs with “slide-out” nozzles

- Exclusive anti-bubbling technology

- Can laning capabilities and no-touch conveying technology

- Sponge rolls eliminates water rim dip and water cost issues, allowing recovery of washcoat material

- Automatic sponge clean and rinse cycle

- Belt support system that minimizes splatter and “drapes” within the can

- Washout mixing and viscosity control

- Anti-catenary magnetic transfer belts for better can transfer

Contact us to discuss your industrial can washer application needs.