Patented automated can washer adjustment system provides the

Industry’s Fastest Can Size Changeover

To maximize production, Cincinnati Industrial Machinery engineered a system that can be used to quickly adjust the different stages of the can washer and /or a dry-off oven, eliminating costly change over downtime.

The Cincinnati Industrial Machinery’s Automatic Quick Adjust System delivers faster, more repeatable can height changeover settings. With the push of a button, a single operator can complete all machine changeover adjustments required for a change in can height through the washer, transfer, and dry-off oven. The patented control system has multiple presets, each with user-configurable product descriptions and height settings.

The prior method of adjusting these stages required manually adjusting a mechanical lever or hand crank for each stage to accommodate various cans. This manual adjustment generally requires the use of multiple machine operators, taking hours to properly set the height for a desired can size, and is not easily repeatable.

Maximize Production | Eliminate Costly Downtime

- Delivers faster, more repeatable can height changeover settings for uptime performance and improved productivity

- With the push of a button, a single operator can accurately complete all machine changeover adjustments required for a different can height throughout the washer, transfer, and dry-off oven

- The patented control system has multiple presets, each with user-configurable product description and height settings

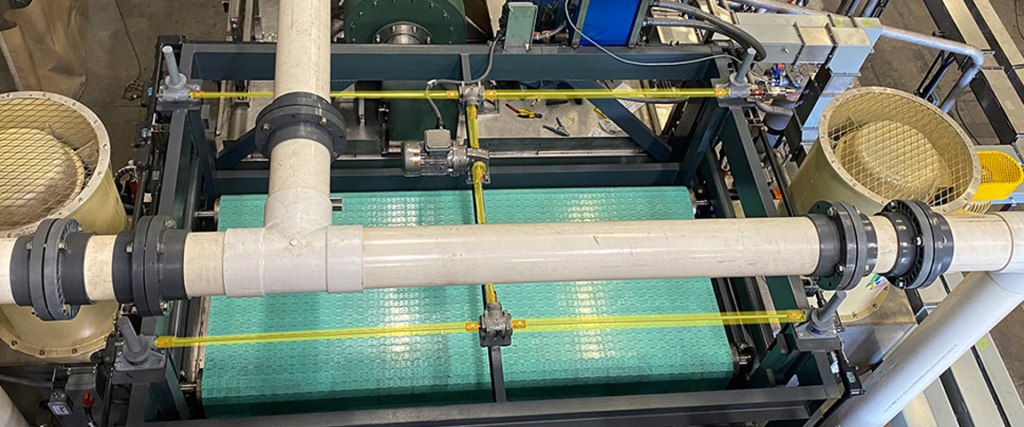

Above Images: Automatic Quick Adjust System highlighted in yellow

Patents: US 10,702,900 & US 11,161,159

Read more about the Automatic Quick Adjust System in the July 2021 issue of The Canmaker on the CIM Blog.