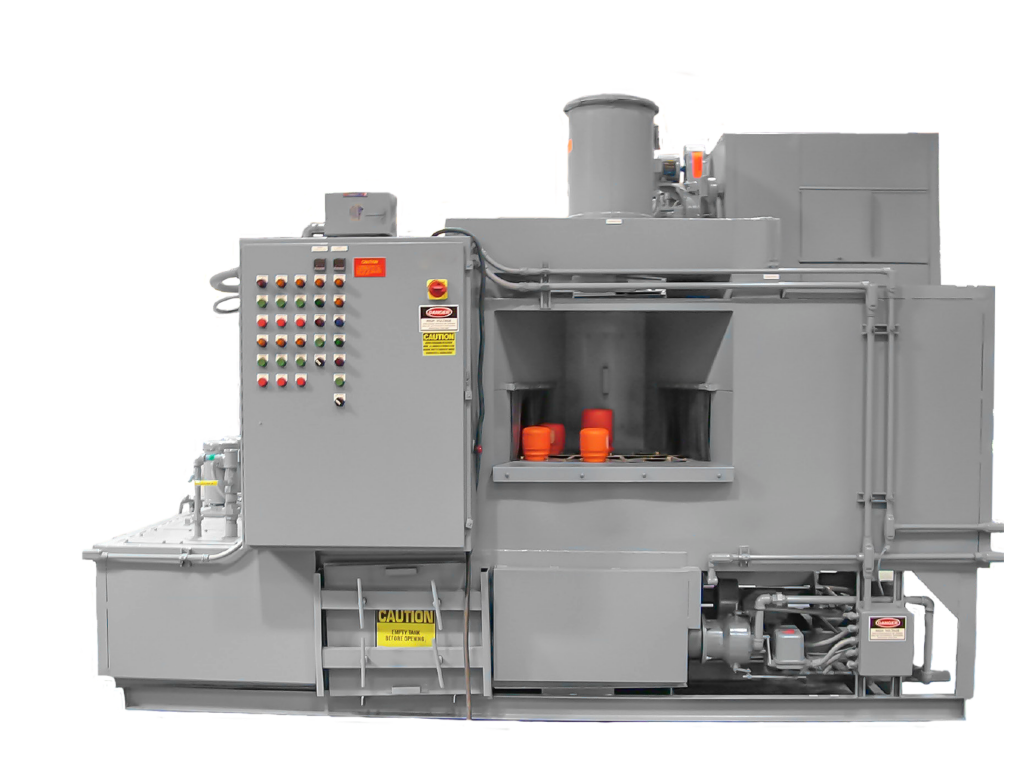

Turntable Washers

Turntable washers are designed to process a variety of parts. They can be arranged for precision indexing applications with fixtured part mounts or they can also handle randomly fed parts or baskets on a continuous basis. The compact turntable design conserves floor space and usually requires only one operator as work enters and exits from the same point. Turntable washers are common in the automotive and remanufacturing industries for cell washing but can be used in other industries for various applications.

Turntable Washer Features

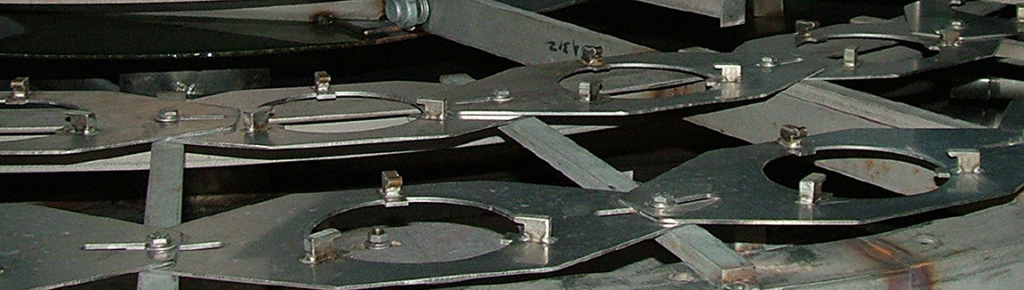

- Stainless steel machine fabrication

- Double welded, watertight tanks

- Quick disconnect riser couplings

- Variable speed pump and conveyor controllers

- Programmed preheat-up of tanks

- Lifting lugs for machine mobility

- Insulated blow-off heating chamber

- Ethernet capable

- Quick disconnect riser couplings

- Clip-on nozzles

- Automatic water fill

- Lift-out splash curtains

- All lubrication points are easily accessible

- Stainless steel round marine doors (single bolt)

- No belts/sheaves on fan drives

- Lift-off tank access lid with stainless steel pump screen

- Lift-off housing access doors

- Lifting lugs for machine mobility

Industrial series revolving turntable parts washers are built with enduring construction, easy maintenance, operator friendly, environmentally conscious, and safety in mind.

Download the sales sheet to learn more about the built-in engineering features and functionality.